Detecting oil spills early to mitigate pollution incidents

The European Space Agency estimates the amount of oil spilled annually worldwide to be more than 4.5 million tonnes1.

The biggest contributor to oil pollution in the world’s oceans (approximately 45%) is represented by operational discharges from tankers (i.e. oil dumped during cleaning operations), with 7% of the oil in the sea directly attributed to accidents. Approximately two million tonnes of oil are introduced annually by such operations, equivalent to one full-tanker disaster every week.

In 2019, a ship carrying Venezuelan crude was the source of an oil spill which tarred the coastline, including threatened mangroves, coral reefs, and whale breeding grounds. The incident polluted more than 2,400km, almost a third of Brazil’s coastline.

The tanker appeared to have spilled the crude about 700km away from the coast and failed to communicate with authorities about the oil spill/release into the Atlantic Ocean. From late August to the end of October 2019, the oil had washed ashore, killing scores of animals and closing hundreds of beaches.

Earlier this year, a bunkering accident released fuel into the water at an anchorage in the Bay of Gibraltar, prompting a temporary closure of operations at the port. However, in this instance, the oil spill was discovered within hours, and removed in a few days.

Jonas Røstad, Chief Commercial Officer at Miros, commented: “Early alarms for quick mobilization are key to reducing the threat posed to marine wildlife and the ecosystem. Early action allows for appropriate spill response to keep the oil from spreading over larger areas, making it easier to combat and avoid further pollution during recovery operations.

“On top of that, a good oil spill detection (OSD) system functions as an aid for the navigation of recovery vessels toward the oil slick and the correct positioning of booms and skimmers.”

The need for oil spill detection and recovery tools

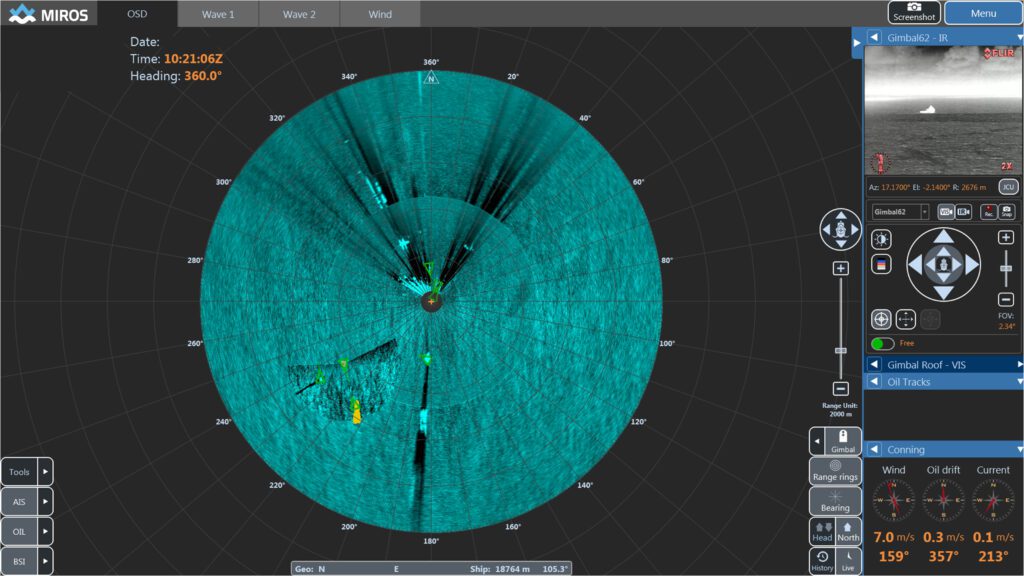

Ocean insights company Miros has developed an OSD system with the unique ability to interpret multiple indicators simultaneously, only triggering alarms when the ‘right’ combination is identified.

Indicators – which include wave height and behavior, surface characteristics, and drift – are collected and analyzed using marine radars, as well as infrared and daylight cameras. The data is then processed, and the appropriate signal is sent to the user interface.

The radar-based system can also be used for oil spill detection during mechanical oil recovery or chemical dispersant operations, tracking the oil slick over time and logging data from the operation to support the post-incident analysis.

The system equips users with early detection and mobilization capabilities, limiting the chance of oil spreading over vast areas and making spills easier to combat. A radar is combined with daylight and infrared cameras, enhancing the system’s detection and classification capabilities, adding valuable information to surveillance or spill response operations, and allowing them to continue in poor visibility, or even at night.

Mr Røstad added: “It is a legal requirement for offshore installations to prepare for the unlikely event of an oil spill. Employing a detection system is an integral part of any contingency plan and significantly reduces the potential for both environmental impact and the cost of response operations.

“It is only recently that ports and coastal locations have started to follow in the offshore industry’s footsteps and utilize more complex oil spill detection systems rather than just visually monitoring the water.

“Whilst containing an oil spill, speed is of the essence as the first few hours are crucial. The difference between using traditional methods versus a radar-based sensor is huge. The gap widens further if a spill takes place during the night as low visibility often means that it won’t be discovered until the morning at the earliest.”

Technology in practice

Earlier this year, Miros’ OSD system was installed onshore, to support a natural gas power plant and its associated water production complex in the Middle East. The operator desired a form of coastal monitoring to alert in the case of an oil spill so that activities could be undertaken immediately to limit any contamination as quickly as possible.

The plant is surrounded by several high-pressure water jets which simulate an environment that displays signs like those of an oil spill, including a shiny, glassy-looking water surface. These conditions must not be misconstrued by any OSD system, to ensure resources are not wasted on false alarms.

The best solution for the company was a combination of a purpose-built Miros X-band radar and a Miros OSD system which were delivered to the power plant.

The X-band radar was installed on a land-based tower, 20m above ground level alongside the OSD system which is highly sensitive to potential oil spills. The system has the unique ability to automatically detect many indicators at once.

After identifying the optimal set of indicators to assess the possibility of a spill, such as wave height, surface properties, and drift, the system automatically activates alarms to signal the potential spill.

The Miros OSD system processes this data, and if required, stores it for future examination. Additionally, the system has the capability to forecast the spill’s path by analyzing offshore conditions, including wind direction.

“Avoiding costly false alarms was key for this project,” said Mr Røstad. “With the water jets of the facility in operation, we customized the OSD system with a ‘clutter map’ which blocked off the specific area that had a high trigger likelihood. This ensured that the correct information was recorded, considerably reducing the chance of false alarms.

“With our technology being highly sensitive, the installation of the OSD system equipped the facility with early detection and mobilization capabilities, capable of detecting a leak within five minutes of it appearing.

“This was a massive improvement on the previous system, allowing for immediate detection rather than the analysis of water chemistry entering the power plant through its reservoirs.”

Why use radar-based technology

Proper and reliable spill detection starts with early alarm generation (with a low risk of false alarms) and encompasses a wide range of criteria: fully automated spill detection with no need for manual intervention; tracking in the toughest conditions and optimal function in low visibility or darkness; slick characterization by area and drift; and the ability to interpret multiple indicators simultaneously to only activate alarms when the precise combination is detected.

An ideal system offers continuous monitoring and can be used either standalone or as part of a sensor network. Furthermore, an OSD system should function optimally whether mounted on offshore installations, vessels, or shore-based stations respectively and have proven efficacy in genuine spill incidents, following thorough tests and verifications in oil-in-water exercises.

Infrared cameras allow any response operation to continue in poor visibility or at night. These are essential tools for spill detection during chemical dispersant operations or mechanical oil recovery and help to act safely, quickly, and effectively, avoiding further unnecessary damage to the environment.

Mr Røstad concluded: “OSD systems are mostly requested for compliance reasons, but we think that shouldn’t be the only reason. Operators should take proactive measures to avoid any negative effect on the environment.

“If a company is forced to implement OSD for compliance purposes rather than an intrinsic interest in having real-time quality data, the process often results in them buying the cheapest system that only fulfills the minimum specifications. Once installed, the system is not used much before the next audit.

“As usability and data quality weren’t top priorities in the first place, upgrading to the latest and greatest product is always a hard or even impossible task.

“Gladly, we have seen a welcome change in the industry’s attitude to OSD. With the goal of giving authorities and operators the confidence that they are using the best available technology to detect and control oil spills, we are currently talking to the industry with the aim of making OSD more than a compliance-driven product.

“Miros developed the first OSD system in 2004 and, since then, we have successfully installed the majority of OSD systems globally. We are continuously looking to improve the system, and our experienced OSD designers are currently running major developmental updates. Our new systems are tamper-proof, ensuring that the data is accurate and limiting the risk for operators to fall prey to bad actors in the event of cybersecurity incidents.

“We see that all parties really want to make a difference in keeping our oceans clean, and ports are increasingly interested in learning of oil spills early to help with mitigation. It’s a welcome move in the right direction.”

References

1 – https://www.esa.int/esapub/br/br128/br128_1.pdf

Bibliography