Directional wave data for structural health monitoring of offshore wind farms

Why is directional wave measurement vital for the structural health monitoring of offshore wind farms? And what role do directional wave radars play?

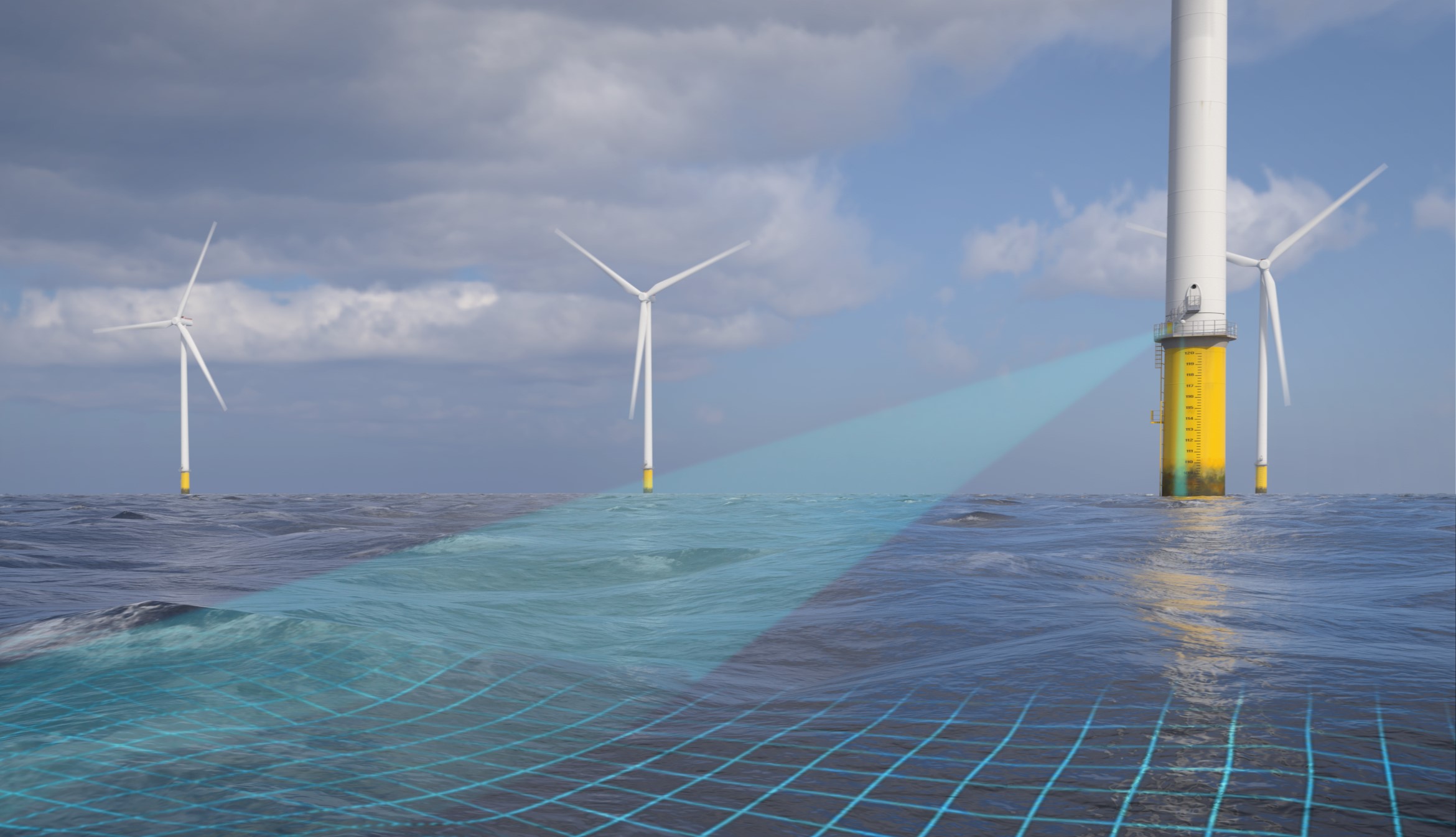

Offshore wind farms stand as monuments to our hunt for sustainable energy solutions harnessing the power of wind over open waters. Yet, maintaining these colossal structures within the dynamic forces of the sea presents unique challenges.

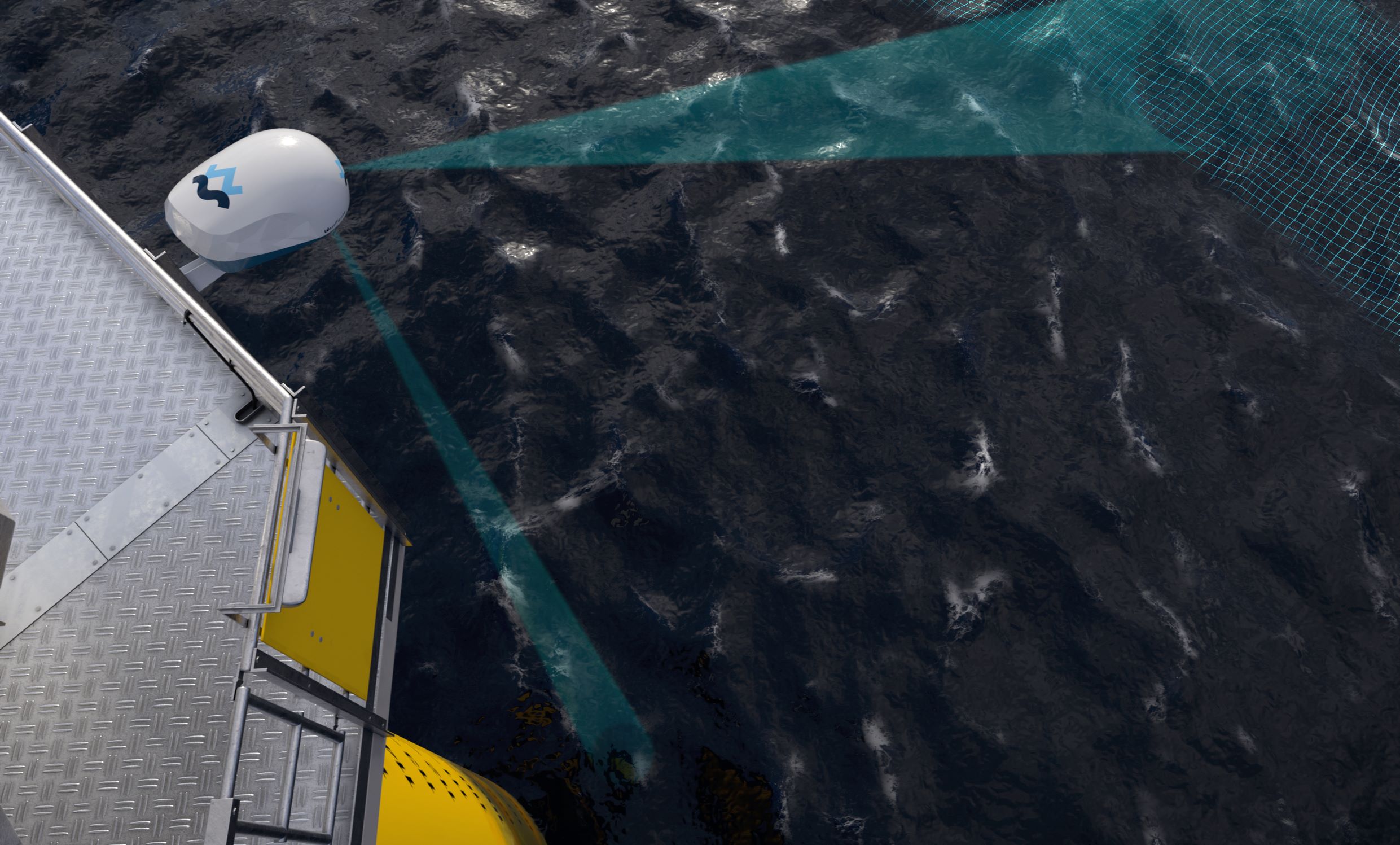

To ensure turbine longevity and efficiency, continuous monitoring is essential. Among the array of monitoring technologies, dry-mounted directional wave radars emerge as indispensable tools, offering a comprehensive view of the ocean’s behavior.

Let’s delve into the significance of directional wave measurement in safeguarding the structural health of offshore wind farms.

Understanding the Marine Challenges

Offshore wind farms endure relentless assaults from the marine environment. Waves, currents, and wind constantly exert forces on the turbines and support structures. Over time, these forces can lead to fatigue, corrosion, and structural degradation, jeopardizing the integrity of the entire installation. Unlike their onshore counterparts, offshore wind farms face additional challenges due to the harsher and more variable conditions of the marine environment. Therefore, precise and reliable round-the-clock monitoring is crucial to detect anomalies early and prevent devastating failures.

The Role of Directional Wave Radars

Directional wave radars offer a holistic approach to monitoring offshore environments. Unlike sensors that measure only the height and period of waves, directional wave radars provide wave directionality, spectra, wave patterns, and intensities which are vital for predicting the load and stresses that wind turbines will endure.

Access to detailed wave characteristics, with higher spatial resolution, and greater accuracy in complex offshore environments is precious for offshore wind farms, where wave conditions can vary significantly from one location to another.

Benefits of Directional Wave Measurement in Structural Health Monitoring:

- Early Detection of Structural Stress: Detailed insights into wave direction, intensity, frequency, and directional wave measurements enable precise structural analysis of the stresses that offshore turbines will face. This tailored data supports engineers in anticipating dynamic load variations, leading to more robust and efficient design and maintenance strategies for offshore wind installations. By continuously monitoring wave parameters, operators can identify potential areas of concern before they escalate into critical issues.

- Optimized Maintenance Scheduling: With precise wave data, operators can schedule maintenance more efficiently. Aligning maintenance with forecasted ocean conditions and real-time sea state measurements minimizes downtime and costs.

- Enhanced Safety: Offshore operations inherently pose risks to personnel and equipment. Directional measured wave data provides crucial information for assessing safety risks associated with extreme weather events, such as storms and rogue waves. By issuing early warnings, based on real-time measurements, operators can take proactive measures to safeguard personnel and assets.

- Data-Driven Decision Making: The wealth of data provided empowers operators to make informed decisions regarding design improvements, operational strategies, and future investments. By analyzing long-term wave trends, operators can optimize the design and layout of offshore wind farms for improved resilience and performance throughout the entire lifespan of a wind farm.

- Compliance and regulations: Directional wave radars help ensure compliance by continuously monitoring sea conditions thus verifying that a wind farm stays within the safety and environmental limits set by regulatory bodies.

Future Prospects, Technology and Sustainability

Offshore wind power is becoming more prominent as the world increasingly embraces renewable energy. With advancements in sensor technology and data analysis, wave radar technology is becoming an embraced solution in the industry, continuously improving especially with the integration of artificial intelligence for predictive maintenance.

Traditional directional wave radars face competition from innovative technologies such as Miros’ WaveFusion. This wave radar was specially developed for the offshore wind market and will be an indispensable ally in structural health monitoring. Through its capability to offer comprehensive insights into the intricate dynamics of the marine environment, this advanced sensor empowers you to navigate the challenges of offshore wind farms with confidence.

WaveFusion‘s accurate real-time measurements combined with forecasted wave data accessible via Miros’ dynamic Forecast dashboard contribute significantly to ensuring safer, more resilient, and sustainable operations.

Continuous monitoring of offshore wind structures is undeniably beneficial. Operators gain advantages in predictive maintenance and proactively addressing structural issues, thereby ensuring safety and sustainability throughout the lifespan of their fixed or floating offshore wind farms.

Miros drives additional innovation in sensor technology and application development, specifically addressing the unique challenges of the offshore wind sector through continued collaborative research and industry partnerships.

Learn more about how you and your team can benefit from Miros’ sensor solutions and applications like Data Connector, Data Explorer, Forecast or Offshore Wind Map.

Find out more about solutions for Offshore Wind.