Optimizing Ocean Data Collection: Strategically Positioning Wave Radars Across Wind Farms

Why is it substantial to optimize sensor placement across wind farms? How to ensure the best capture of your wind farm’s wave condition variations?

Let’s talk about why it is significant to get your offshore wind farm’s wave monitoring system positioned correctly right from the start. What difference does a specific sensor placement make?

In the past, many offshore wind farms had the wave monitoring system set up by putting a wave buoy on-site for a pre-construction condition monitoring campaign. And this configuration often stays throughout a wind farm’s 25+ years of Operations & Maintenance phase.

Despite this approach ticking requirement boxes at the time, in recent years it has become more prominent that offshore wind farms switch to dry-mounted wave radars once the turbines are installed.

The main reasons are:

Wave radars are more robust towards the same weather, whereas sensors submerged in water get greater impact over storms.

Sensors submerged in water are more costly to maintain and require regular maintenance.

Dry-mounted wave radars often boast a better data transmission system to achieve real-time data sharing with users remotely.

So, if you are working for an offshore wind farm and are considering deploying dry-mounted wave radars as your site’s wave monitoring system, where should you best install them?

At the start, most offshore wind farms would prefer to install the wave radar(s) on substation(s), taking advantage of the substation’s better electrical and data transmission infrastructure. Beyond that, many sites simply put the additional wave radars to the far corners of the site.

However, from our experience, we have seen many sites with different amounts of variation in wave conditions across the site. For example, if the west side of a wind farm tends to have more uniform waves than the east side, it would be more beneficial to have more sensors on the east.

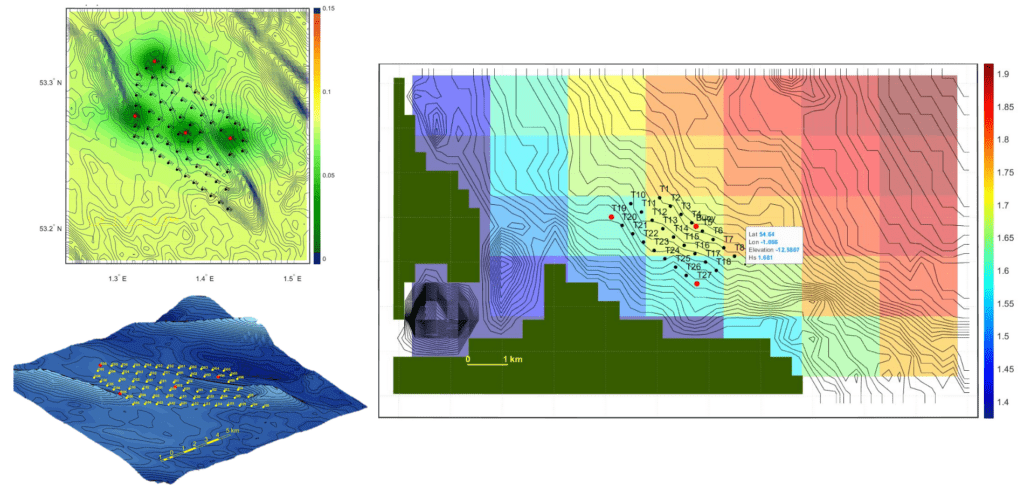

Sensor Placement Optimization

With this improvement in mind, Miros provides an analysis service based on our Sensor Placement Optimization Tool (SPOT). SPOT takes in historical wave data from the offshore wind farm location, bringing together bathymetry data and the coordinates of turbines or platforms. The algorithm calculates wave variation in this area and lets us input the number of sensors that are to be installed on-site. SPOT then highlights the optimal locations for placing these radars. Furthermore, the algorithm can be customized to focus on wave heights near your operation vessels’ operation limit. Suppose a site will mainly be serviced with crew transfer vessels (CTVs) with an operational wave height limit of two meters. In that case, Miros can tailor the formula to be most sensitive at wave heights of 1.5m to 2.5m, and not take into calculation when the wave height is below 1m or above 3m when the sail or no sail decision is clear.

If you are already on the journey of implementing the best wave monitoring solution for your offshore wind farm, this may just be another valuable component we can help with.

If you are interested in finding out more or sharing your site’s challenges, please do not hesitate to get in touch.

Learn more about how you and your team can benefit from Miros’ sensor solutions and applications like Data Connector, Data Explorer, Forecast or Offshore Wind Map.

Find out more about solutions for Offshore Wind.